Superbowl Sunday! Since the Niners were not in the running, it was a perfect time to spend the day playing with planes. As usual it started with the basic prep of the parts. (Clean with EcoClean, then etch with EcoEtch). I had a big appointment with Nico to fly his new RC plane, so I got up early and snuck in as much prep as I could before the rendevous.

Not only did I get to go fly RC planes with Nico, but Jack and I also had a great lesson. He is working on his patternwork and has gotten to the point where he is landing on his own every time. Emergency Landings..here we come! Between those dates, I wrapped up the prep work.

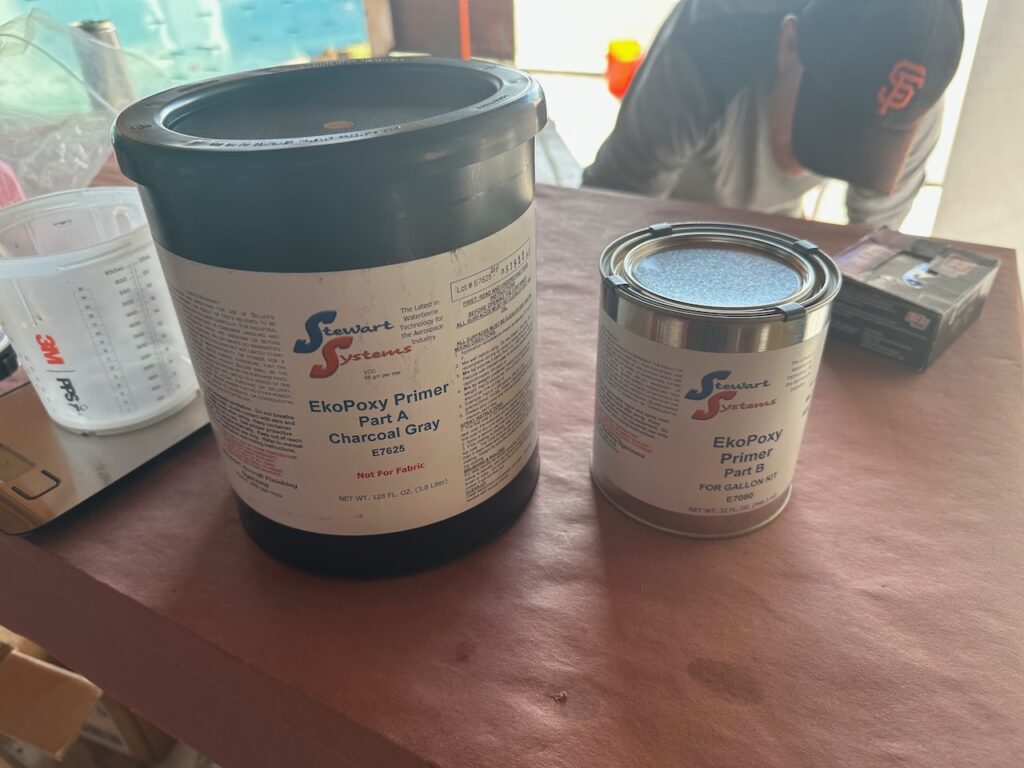

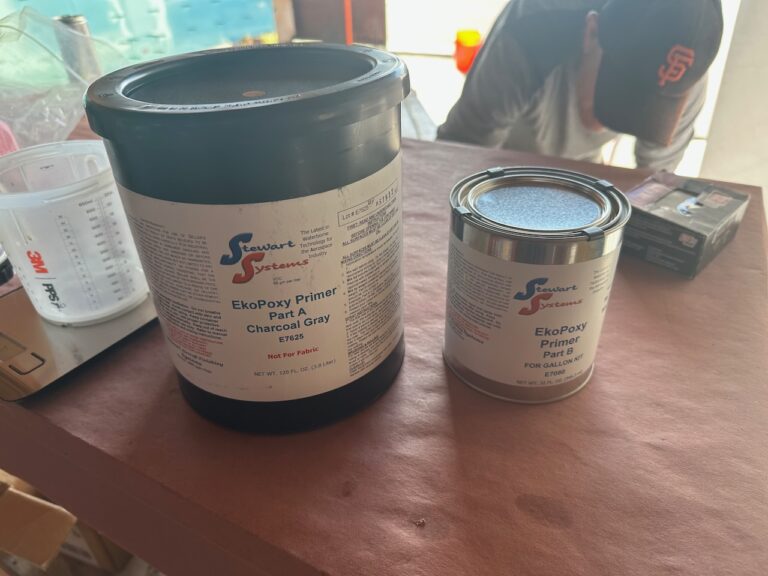

Sam came by in time for Super Bowl and priming! We set up the booth and reconfigured the work area for prime management. One difference this time around is that I am now using a two part epoxy primer. This type of primer is significantly more resilient to fuels, oils, and human touch. Because the fuselage has many parts that will be exposed to these elements, it makes sense to switch. The complication is that two part epoxy primer requires precise mixing of Part-A and Part-B to ensure proper curing once applied. The formula is Part-B is 18% of Part-A by weight (and also water at approximately 15% of Part-A). The issue is that Part-B is much harder to meter out since there is no pouring mechanism (it’s just a can). Sam and I decided next time we will pour Part-B first, then reverse engineer Part-A and the water. The only other issue I ran into was the paint gun seemed to have poor spray in the last session. I attributed this to running out of paint, but in hindsight it seems like the real problem was the paint reservoir starting to produce a back vacuum reducing effectiveness of the gun. I’ll watch out for that next time.

I was pleased with the outcome below. Notice the new darker grey. Honestly…the choice was in error (I couldn’t remember if I had smoke grey or charcoal grey), but I actually like the color better, and will stick with it going forward. With all the primed parts, it’s time for the fun part… assembly! Hopefully this coming weekend. Until then…. Happy Building!!

5 comments

Nice work as an aeronautic engineer and as a Dad. The fuselage is moving quite fast. More fun to come 😁

Cool

Tent!

That paint tent in the middle of the hangar is a genius idea! Every time I paint in the garage the smell would last for days haha.

It’s great for keeping things tidy. The one down side is how long it takes to set up and take down. Thinking about a v2 for smaller paint projects that isn’t so time consuming. Thanks for reading!