There’s no other way to put it…these priming days are brutal. Especially when mostly working solo. The tough thing about them is that once you get going, you really can’t stop. You just need to plan a full day, and power through the process. In this case, starting at 5:30am, and cranking for 13.5 hours straight, I was able to get through all the steps, and come out of the day ready for some fun final assembly work. Check out the details below.

0530 - Prep, organize, and clean

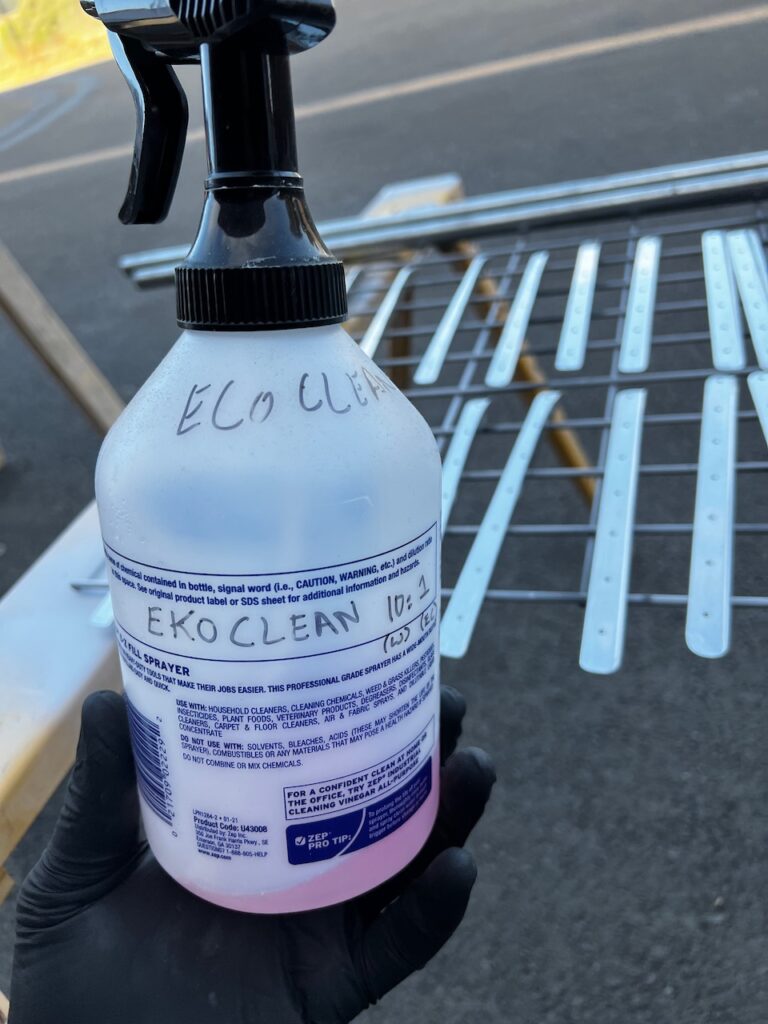

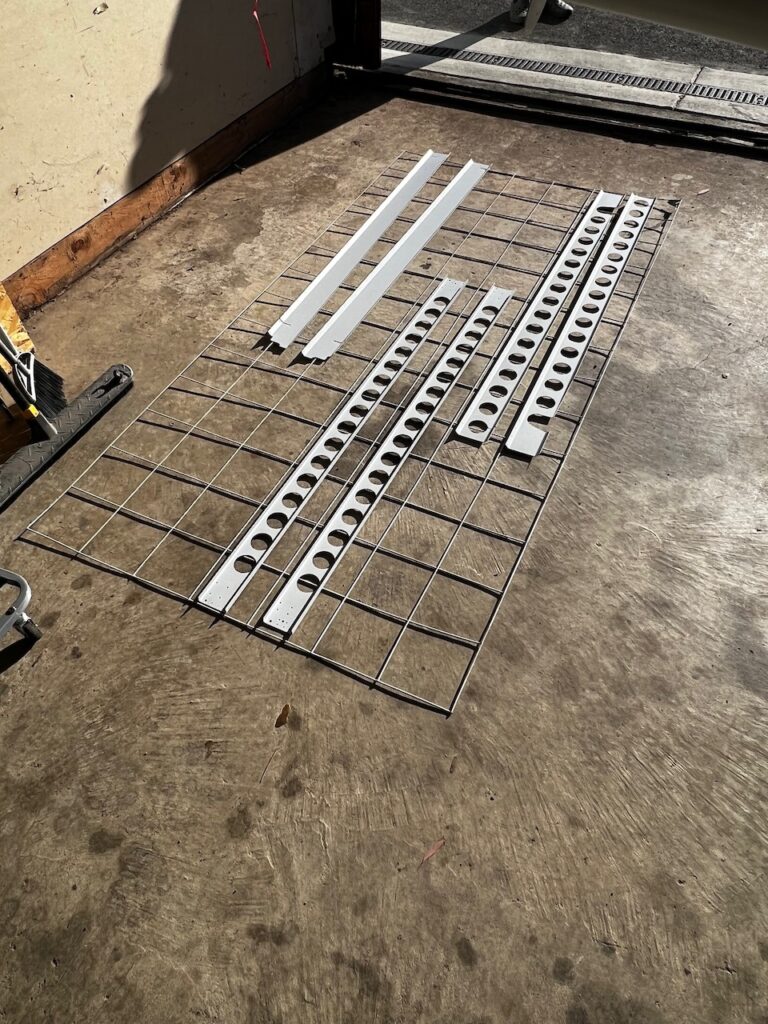

Most of these sessions I start around 11am, and find myself going late into the evening. By starting earlier, I was hoping to get the paint booth work done during daylight, avoiding some of the challenges of working in the evening (Spoiler alert…it worked out great, and got to prime during the perfect lighting hours). After getting my water repository filled up, and heading out to the hangar, I started by arranging all the parts outside, and using EcoClean to degrease and clean the parts. It was really nice doing this in the cool shade of the morning. Later in the day, it gets brutally hot with th direct sunlight.

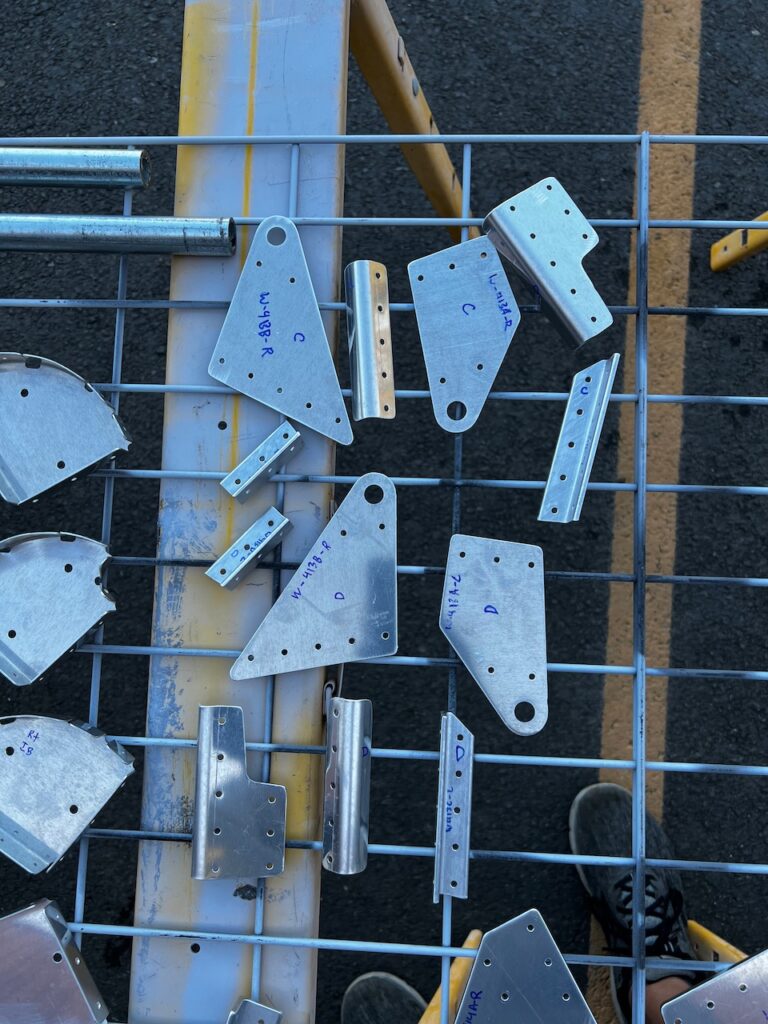

0900 - Etch, etch, etch

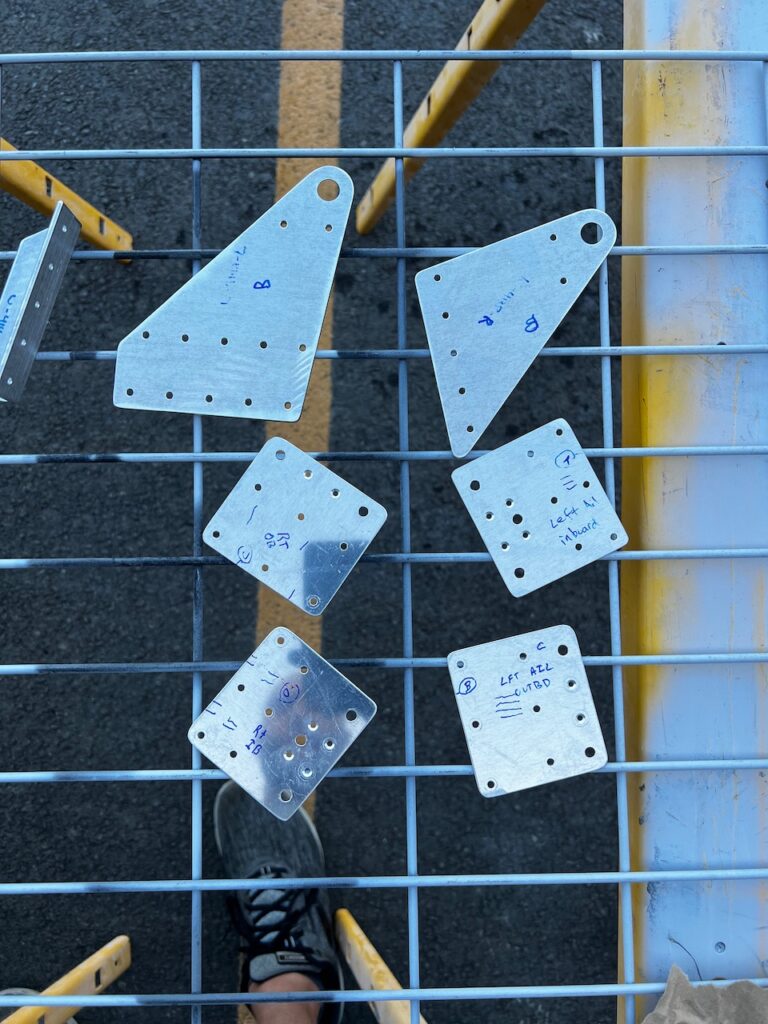

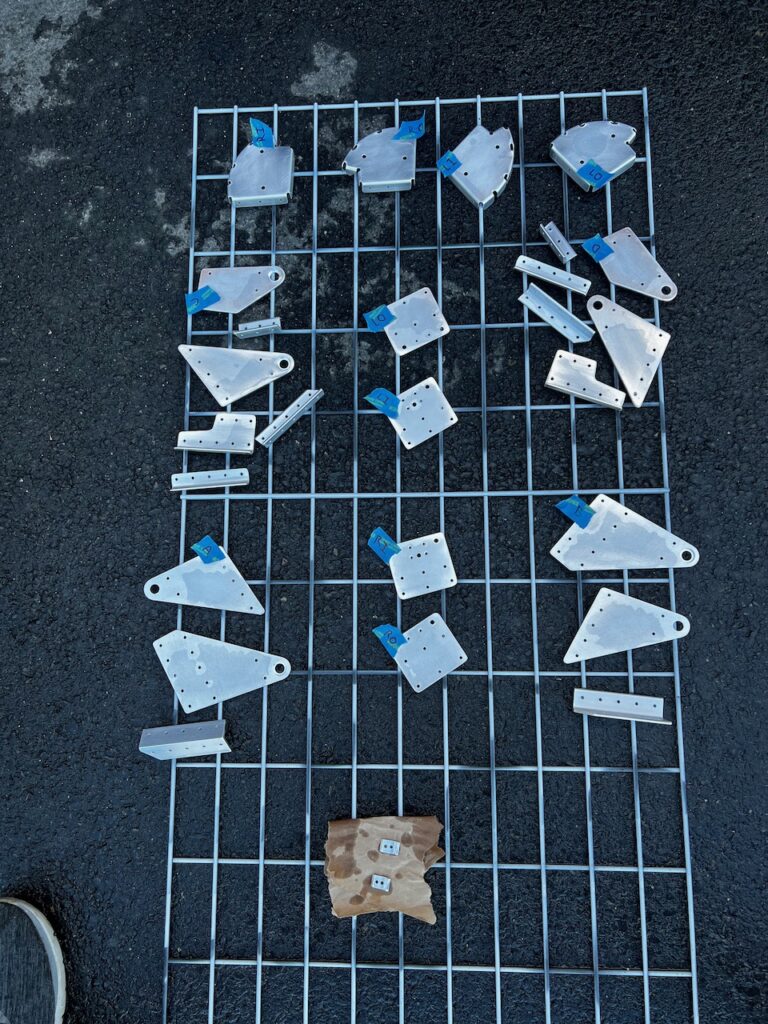

As usual this is a nasty part of the day, but necessary to get a strong bond between the primer and the aluminum. Once the etch is sprayed on, you have three minutes to scuff up the parts with scotch brite before needing to rinse it off. If you don’t do it speedily, the chemical etch will start to eat into the aluminum. This requires small batches, so with a ton of small parts it just mathematically takes a long time. The chemicals are fairly nasty, so doing it outside is a must. After etching, I needed to temporarily re-label as the etching wipes out the markings so I used blue tape to label the parts as I let them dry. Then I’ll transfer those to the actual part. After 3.5 hours, the etching was done!

1230 - Paint booth prep and organize

While the parts were all drying from the etching, it was time to do the conversion to a paint shop. I’ve gotten pretty comfortable with this process.

- Get everything down from the attic (booth, fans, exhaust hood)

- Gather other booth equipment (extension cords, air hoses, paint gun, paint, etc)

- Set up booth and inflate (the rest of the day is loud…think bouncy castle loud)

- arrange all the parts in the booth and ensure lighting is good for priming

- use tack cloth to do one last part cleaning (minimizes lint, dust etc on the part)

1500 - Paint booth (and Boba!)

Honestly, this part of the day is fun. Besides sweating up a storm since it was 80-90˚F out, putting on the bunny suit and getting quick 5 minute sessions per coat is satisfying and relatively easy. Between sessions it’s generally miscellaneous tasks like cleaning the workshop, reading up on next steps, and watching the baseball game. 30 minutes later, it’s back in the booth. 4 sessions like that (2 per side), and you’re done! The best part was my mid-afternoon boba and Bahn Mi sandwich I knew was waiting for me between priming sessions. Yummy!

1730 - Breakdown, Cleanup, and Celebrate!

It was 5:30pm and I was done with the hard work! Whew. Tod came by and helped keep me company as I wrapped up the shop and converted it back to it’s normal configuration. One thing to note, I didn’t mask off the skins and so got a bit of overspray that will need to be cleaned off. I did an initial cleaning which got 90% of the overspray off, but will get the rest once everything is riveted together. Next time, if I just mask off the edges, I think that’ll solve most of the issue. Overall the day was a success, and I got everything I wanted to accomplished!

And 13.5 hours from starting pre-dawn, I’m all done! It was a long and grueling day, but now have a ton of parts ready to do fun stuff…building the ailerons! I’m glad I got this knocked out and relieved I can move on to smaller more incrementals sessions. Next up I will start with the aileron brackets, then move on the the gap fairings, and flap brace install. All major milestones toward wing completion. Until then…Happy Building!

1 comment

What a marathon. Wowww. That a full day and than some. Nice work…. Before you know you will be idle waiting for the toy next batch of parts.