Have I mentioned how happy I am with the setup of my workshop? Everything is where it needs to be, and I am now able to run down to the hangar for a quick session, and get up and running within 5 minutes of arriving. I particularly like the air hose setup I have on one of the benches, which allows me to have 3 tools connected at the same time. And each tool is connected to a light weight 10′ hose. The hard work setting up the shop has definitely paid off. I’m curious how warm it will be in the winter, but for the current weather it is an extremely pleasant place to work.

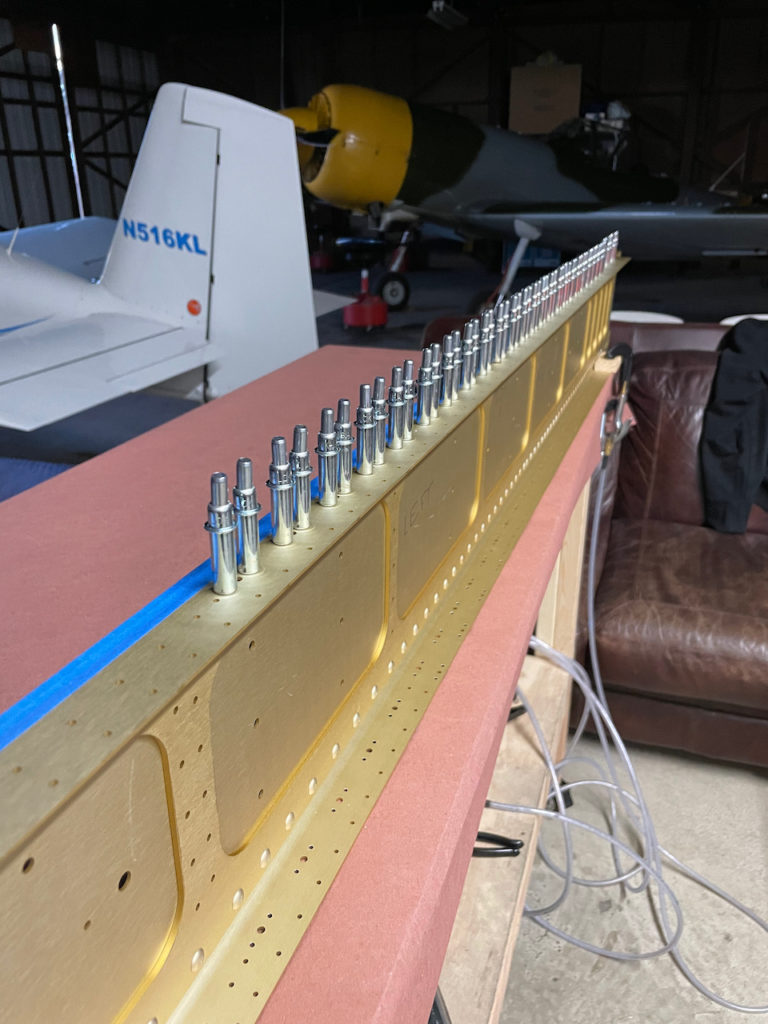

Today I got a good session on the left main spar, completing all riveting of nutplates for both the tank skins* and the access covers. I ended up re-countersinking a lot of the holes to ensure the flushness of rivet was cleaner than the right side based on what I learned yesterday. I’m happy with how it turned out.

* there were a few rivets I couldn’t get to with my current yokes (the angled nut plate rivets closest to the spar webbing), so I’m going to borrow a thin nosed yoke from a fellow builder on the field to finish off those.

Next session I will start countersinking the holes for the #8 and #6 screws, and will need to make a dimple template to ensure the hole is large enough to allow the skin to sit flat. But for now, I’ve put the main spars back on the wall and cleaned up the shop for the night!