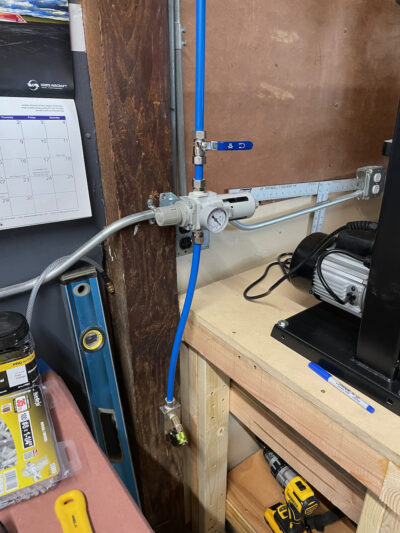

With the kit literally days away (it’s sitting in a warehouse 30 minutes south of where I live), I was starting to get anxious about trying out all the equipment and making sure I’ve got a good feel for where the shop is at. Conveniently, I have 4 different practice kits I can “warm-up” on. 2 Van’s toolboxes, a Van’s Lightbox, and one that I forgot about, a Cleaveland “Phone holder” kit. I decided I’d start simple, and tackle the phone holder. I plan on building the Lightbox on my own, and working with each of the boys to build a tool box. To do so, I needed to hack together the air system, since not all the parts are available to do the final mounting. Don’t Judge me:

The featured image was first attempt, and after realizing that I didn’t have a regulator, the above solution is what I ended up with. Yeah, I know..it’s UGLY, but it worked. I really wanted to get to some building (that wasn’t wood) today. To ensure I had an end to end test, I installed the mini NPT port to the pneumatic squeezer, and hooked up the manifold to the outlet above. Tested and….perfect!

Yeah, that thumb cut from yesterday is a pain with the squeezer but I’ll manage. So I was ready to build the phone holder practice kit. I started to read the instructions, and required tools.

- Grinder – check;

- #40 reamer and bit – check,

- cleko gear – check;

- squeezer, yokes, sets, rivet gun, bucking bars – check, check, and check!

- Back rivet set, and back rivet plate – check and…uh..check..sort of.

back rivet plate install

I ran home and got my compact router so I could carve out the spot for the plate. After marking the location, adding 2×4 backing underneath (yes that’s my son sleep on the couch), I clamped down the guide rail, and started routing away.

After some time, and a bit of clean up of the corners to square them out, I ended up with a great fit, and a back rivet plate that is now useable!

It’s time to get back to the phone holder build! Hopefully I didn’t forget anything else I need to prep in the workshop. After reading through the directions, i felt pretty comfortable I had everything I needed. Look out for the next post on the phone holder build! So excited to get to some actual metal working!!