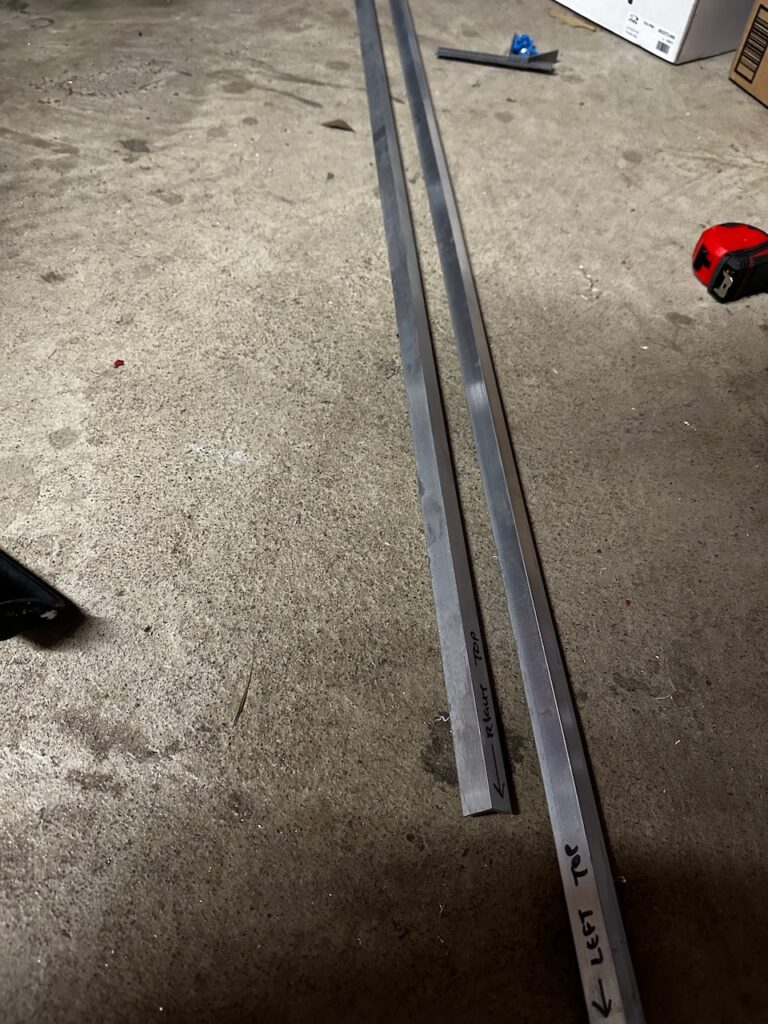

This weekend I had two great sessions. In the first I was able to start the tailcone attach including the first time I saw the full length of the fuselage. In the second session James and I made massive progress including the dreaded F-887 longeron bend. In session one, there wasn’t much of note. The only awkwardness came from getting the logerons onto the aft skins since they were so floppy. It would have been nice to have a large flat table to work on…but all of those are currently occupied!

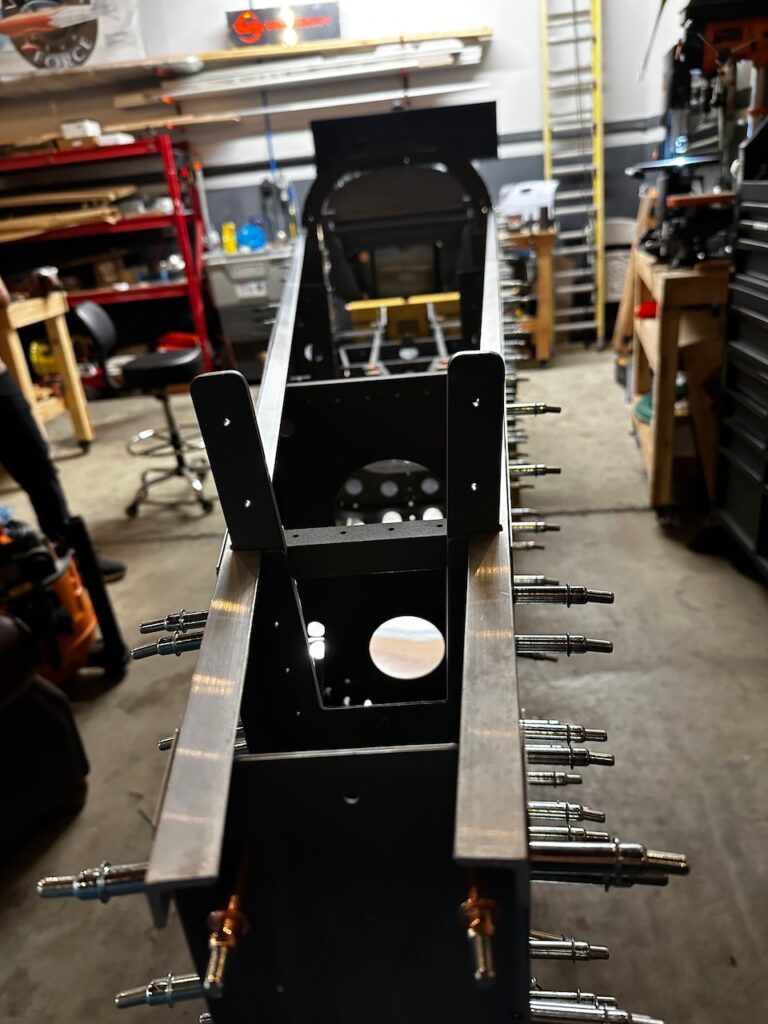

Before we got to the Longerons James and I cleaned up the edges of the aft bottom skin (F-842) and cleco’d it to the bulkheads and side skins. It was actually quite challenging as the holes did not want to line up. We fould that moving one hole at a time, and slowing working your way fwd or aft made for better alignment. With all the curves and angles I’m not surprised at how challenging it was. After an hour or so we had the bottom skin on!

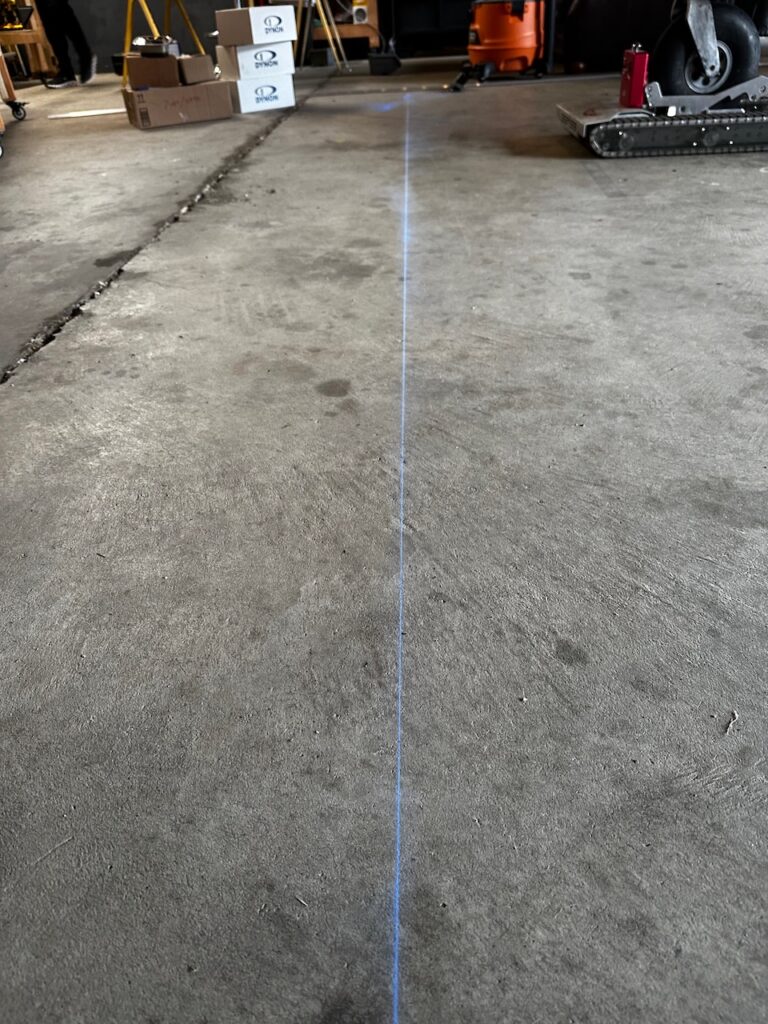

There are a few steps that seems to garner elevated levels of discussion on the Van’s forums. The longeron (F-887) bending is definitely one of those steps. It is a step that is called for quite earlier than I ended up performing it. I recommend the way I did it. If you bend the longeron before you have a visual of where it should go…I imagine it is much harder to get it right. There are also a few other tips I would recommend:

- have someone help – James and I did this together and it would have been a total pain to manage the super long longerons without him there. It’s also great to bounce the plan off of.

- measure multiple times – these parts would cost a lot to replace…mainly due to the shipping so measure things multiple times.

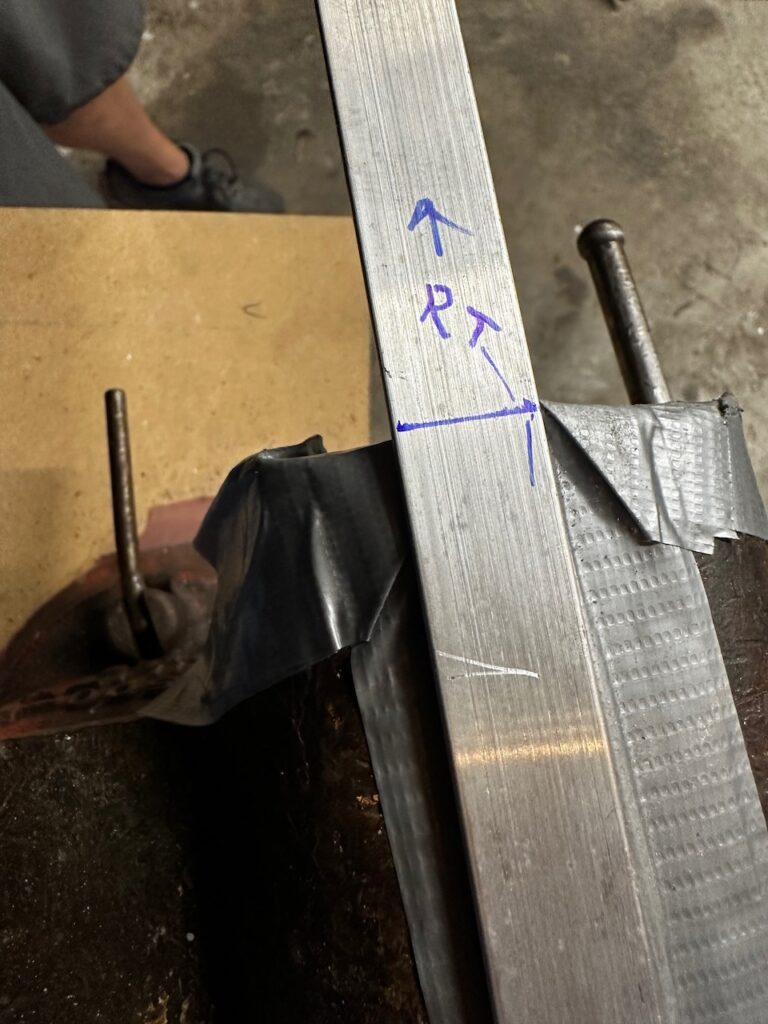

- mark everything with orientation marks – James came up with this marking that helps avoid bending the wrong way. See below.

- don’t worry… just go for it! – We just took our time and in about 1.5 hours we had both longerons bent and fitted! It was way less intimidating than the anticipation.

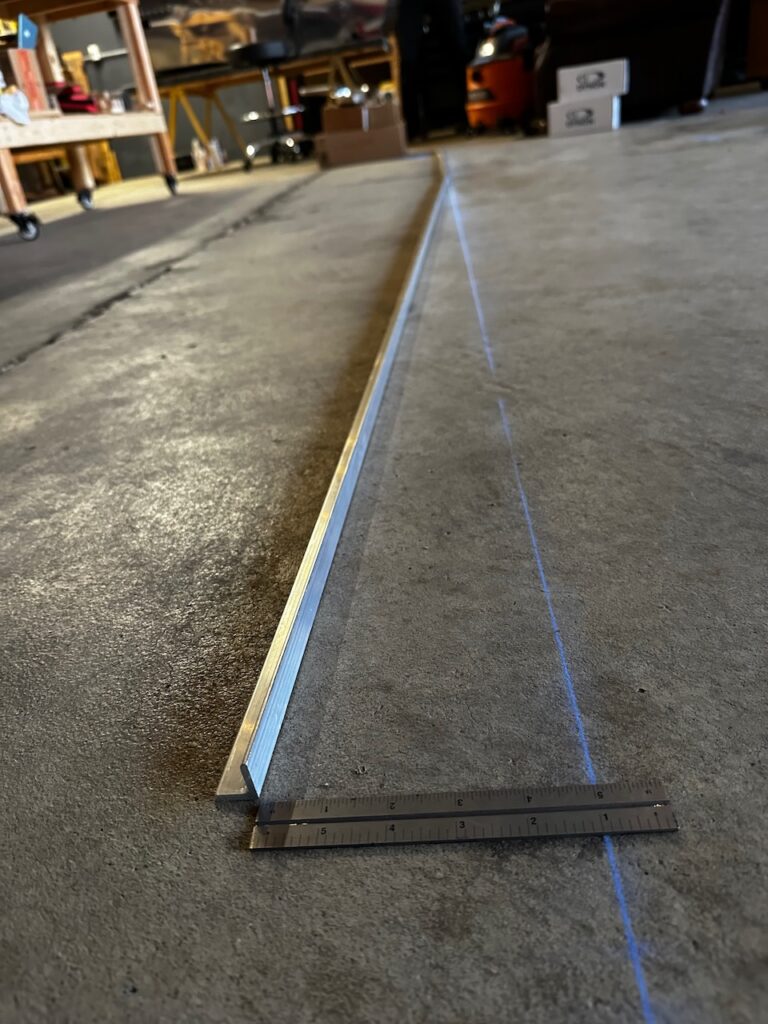

And just like that (and hours later) we had the longeron’s bent, fitted, and in place for drilling. What a big step! Next up will be to put in the remainder of the fuselage parts needed for final clamping and then a whole lotta drilling! Until then… happy building!

5 comments

All I can say is Wowwww. Fantastic progress

Looking like and airplane!

Thanks Steve!! Maybe another plane to wire up in 2025? Or at least a whole bunch of phone calls… ha ha.

No! 2024! C’mon Paolo where’s the optimism?! 🙂 🙂

Ha ha! With your optimism (and labor) it might be possible!!