It was nice to take a break from sealant work, and be able to do work without a mask on. I also got to another first as I learned how to flare aluminum tubing and connect AN833 parts. See below for some detail on a fun afternoon of learning new skills!

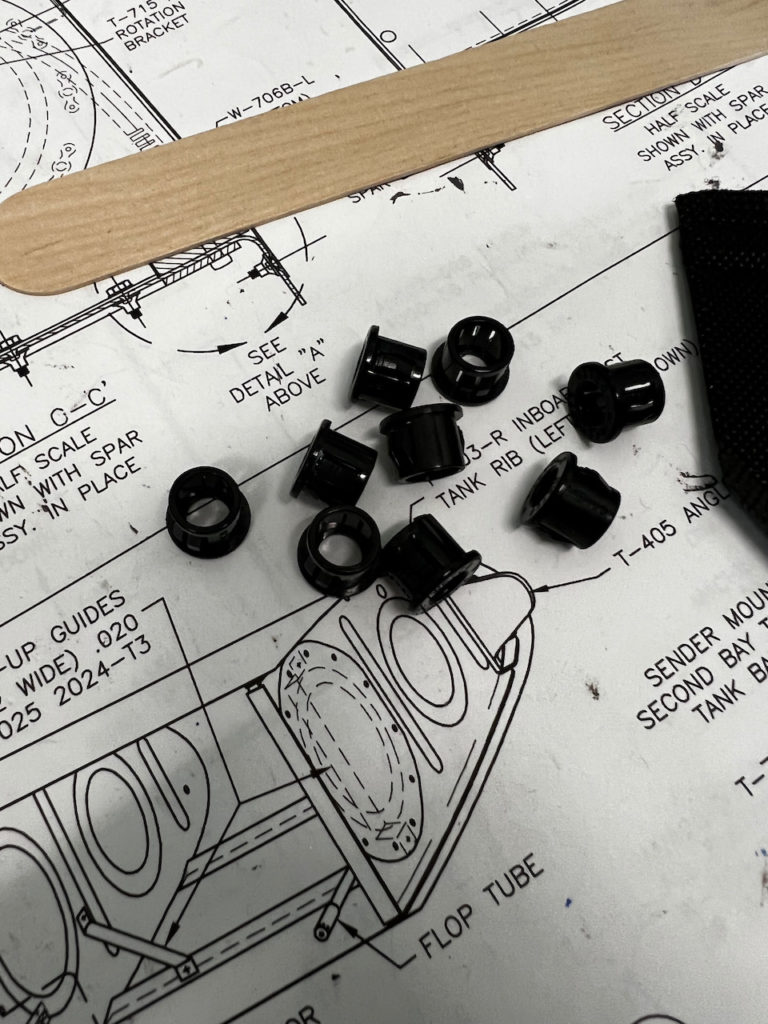

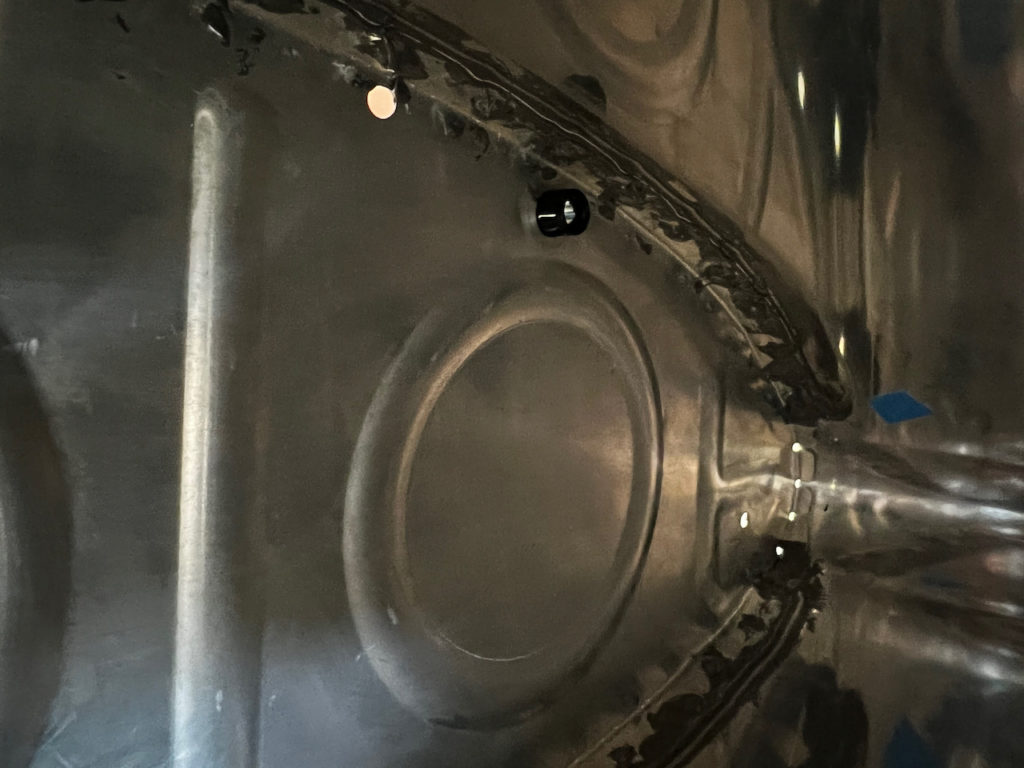

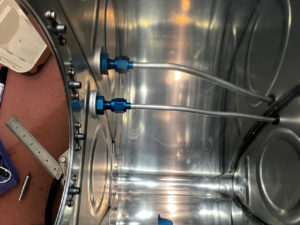

Most tubing and conduit requires bushings to stop the aluminum ribs from cutting the lines. In this case, I used SB437-4 bushings that came with the kit. They popped right into the holes already machined out of the ribs. Next up was cutting the line, straightening it, and doing a test fit in the tank. This also allowed me to refine the cut before starting the flaring of the fitting end.

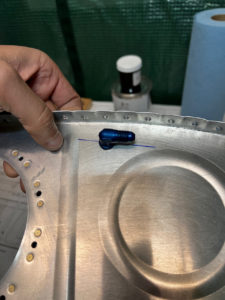

So once I got the line rough cut, I realized that I needed to cut the hole for the vent line fitting into the inboard rib. This was easy with the unibit drill bit. After deburring and test fitting the pieces, I reinstalled the inboard rib to mark final length for the vent line.

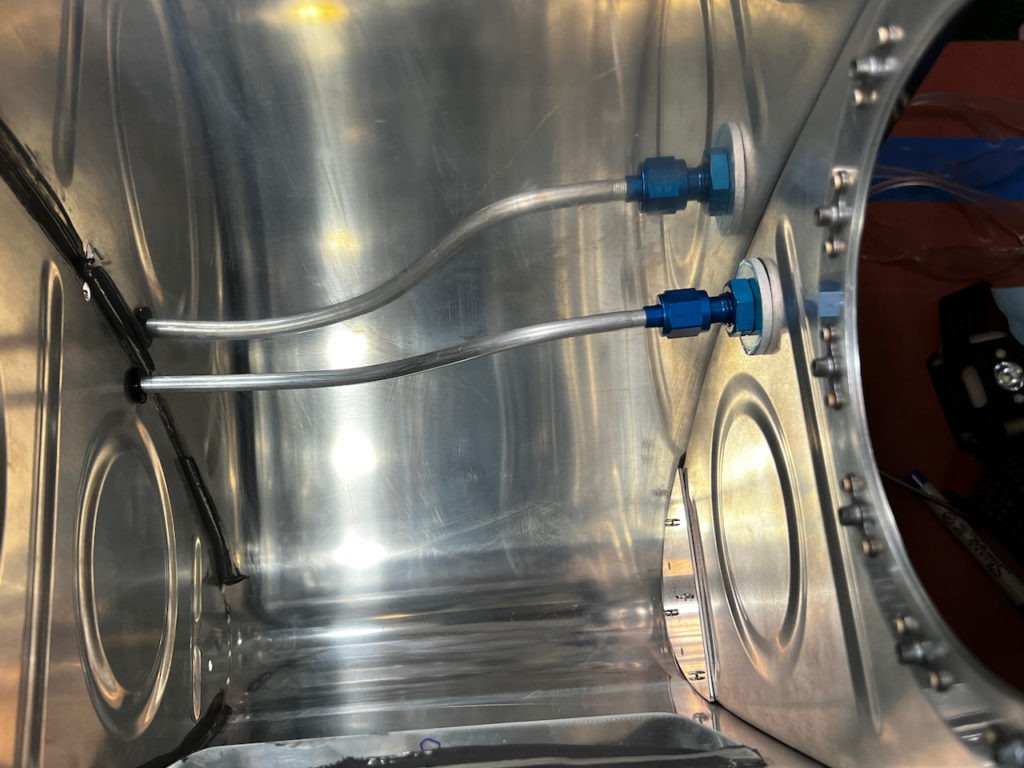

Note that I marked the final length to the end of the flaring rim of the AN833 part. That is because the way the line connects to the fitting is through a flare and connect parts. Since it was the first time I’ve used my flaring tool, I ran a couple of test trials, and once I felt comfortable I could flare consistently I flared the actual fuel vent line. It was definitely worth practicing a couple times as it took a couple tries to get it right (don’t forget the tapping oil and putting the line in the correct side!)

Note the bend in the inboard bay. I’m not sure the functional reason for this, but it sure helps to have some flexibility on getting the line length fitted properly. After completing the right tank, I did the same thing on the left side.

All in all, a fun and fulfilling session, and one step closer to final closure. I’ll verify tonight, but I think next step is install of the inboard rib. Hopefully I can take care of the first one tomorrow night. Until then, Happy building!!

2 comments

So much detail !

Nice work. I was noticing the quality of the material: everything seems to be the absolute best. After thinking about it I realize That it was needed to match the ability of the assembler. 😂😂