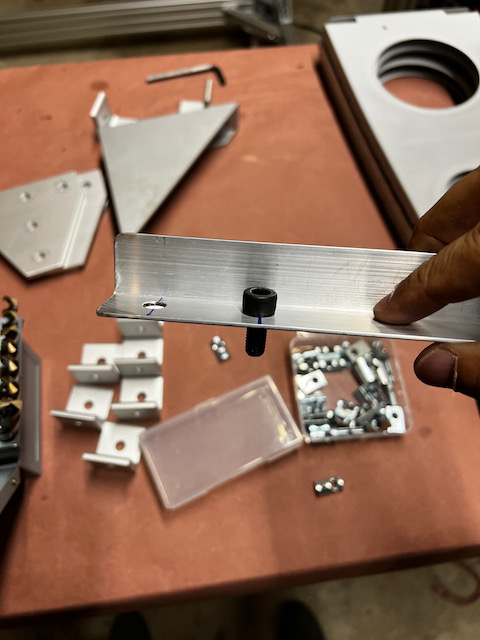

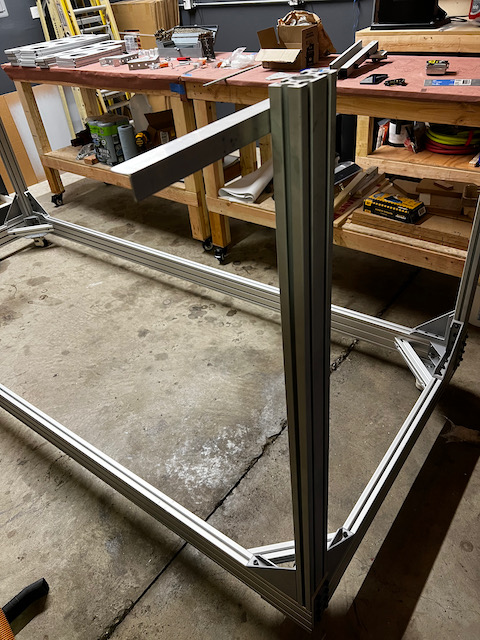

This morning I was eager to get the “shelves” that will hold the spar up. I was curious if the measurements were correct, and how rigid the system would feel. I needed to fabricate angle brackets that would mount to the towers, and provide the appropriate width for holding the spar. It will get clamped down on one side, and bolted together on the other. After marking the lines for drilling, and calculating the center points, I used the drill press to drill for M8 bolts (21/64″ drill worked for me).

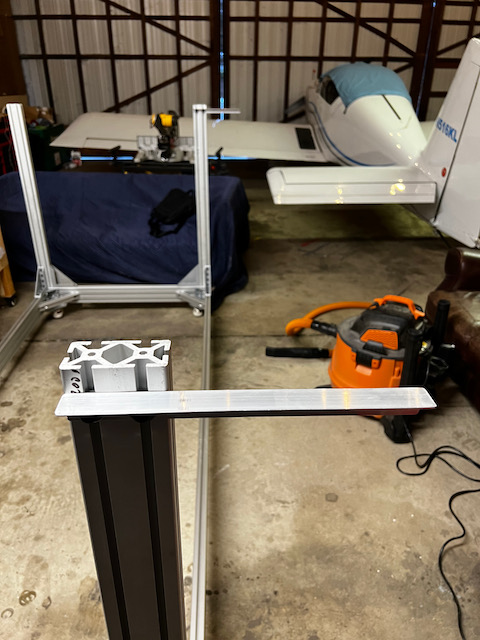

Most folks use a threaded rod to allow adjustment of the angle of the shelf to account for possible wing twist. I tested out the fit on the tower and realized that with the double channel of the 8020 tower, I could make easy adjustments for level, and still provide significant rigidity without the threaded rod. Woo hoo for over engineered structures!

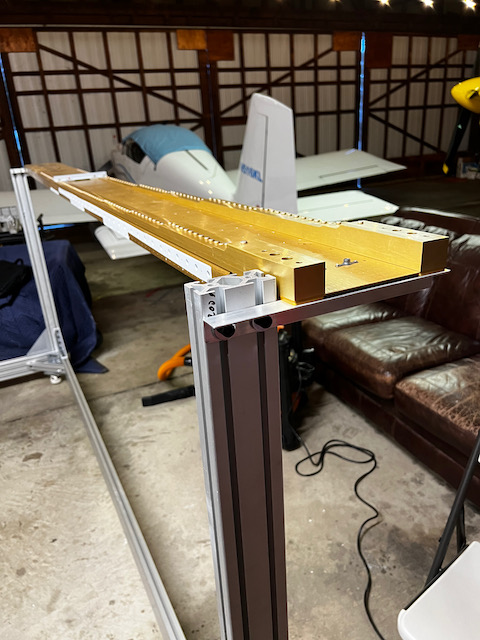

I was able to fabricate 3 of the shelves, but did not have enough to complete the last one. One thing to note is the orientation of the shelving. You’ll notice that one is “inside” the tower, while the other is not. This is on purpose, as the wing ends are different. On the outboard side, I’ll need to actually temporarily attach an angle to the wing rib, and then bolt that to the shelf. On the inboard side, I will actually be using a clamp to hold the spar in place. Since I wasn’t going to be able to finish the shelving, I figured a ceremonial first check of the spar was in order. Turns out all the planning worked out well!

If you look closely you’ll see a bit of sag in the wing spar. This is expected and will require a leveling mechanism around the mid point of the spar. In my next session I plan to build those leveling shelves as well as complete the other side. That should be the last piece of the wingstand before I can put it to work!