Finn is an old colleague of mine that ranks up there as one of the hardest core engineers I’ve ever met. If you have something that needs to be built…he can build it, If you have software that needs to be written….he can write it, and if you happen to have a silly wing stand project that should be slapped together with a few pieces of wood…he will help you instead build the most robust wing stand in history! I went down to his workshop about 30 minutes away (which was absolutely beautiful) where he has access to a nice supply of 8020 Aluminum. Rummaging through it he determined there was enough for us to build the stand and so the planning began.

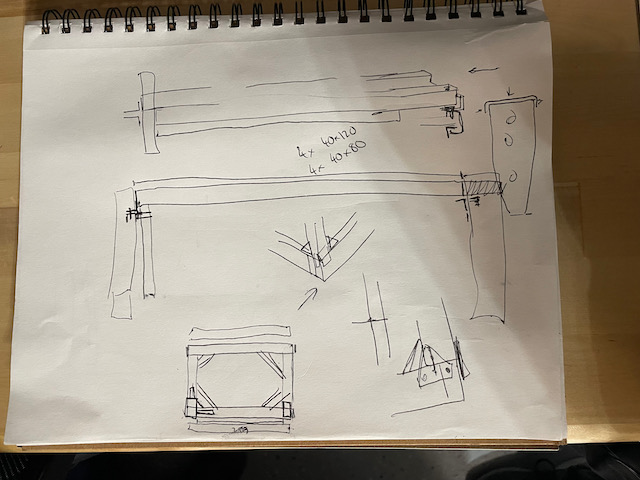

Finn’s workshop is a veritable Disneyland for any maker. Full dust collection system, electronics workstation, and parts galore. His cabinet probably has enough widgets and gadgets to put together a full avonics system. He also has a lot of 8020, which is an extremely strong aluminum extrusion that is basically like oversized Erector set pieces. Once you have a design, you simply cut pieces to length and decide what “connectors” you need to secure them all together. Most of our evening was sketching out ideas (and eating tacos and drinking beer!) and after deciding on a final design, the part collection started.

Obviously it’s important to get the dimensions correct before cutting the fairly costly 8020 pieces, so I made sure to get final measurements on the spars and ribs. In metric measurements, the spar measured out to 2903mm, and the main ribs were 673mm. The former is important for the span of the stand, while the latter dictates minimum height of the stand. For me, I don’t think the height will be an issue, as I’ll likely build it relatively tall since ergonomically that works best (I’m 6’6″). Once we got everything measured out, cutting began. Cutting the metal required 2 of us to make sure we had cutting oil, vacuum, and saw operations all covered. The cutting required masks as some nasty smoke comes off the saw.

The night ended with full bellies, a full car of 8020 parts, and a couple empty bottles of excellent Belgian tripel. Thanks to Finn for teaching me about 8020, and generously donating some of his material to the cause. Looking forward to assembling the stand and putting it to use!

5 comments

The adventure continues. The learning increases. The product will be beautiful

excited to get this thing put together!

You have to build everything custom !! EVEN. The stand… we can be there n see this week or next ?

of course! You are always welcome to come by the hangar.